Principle

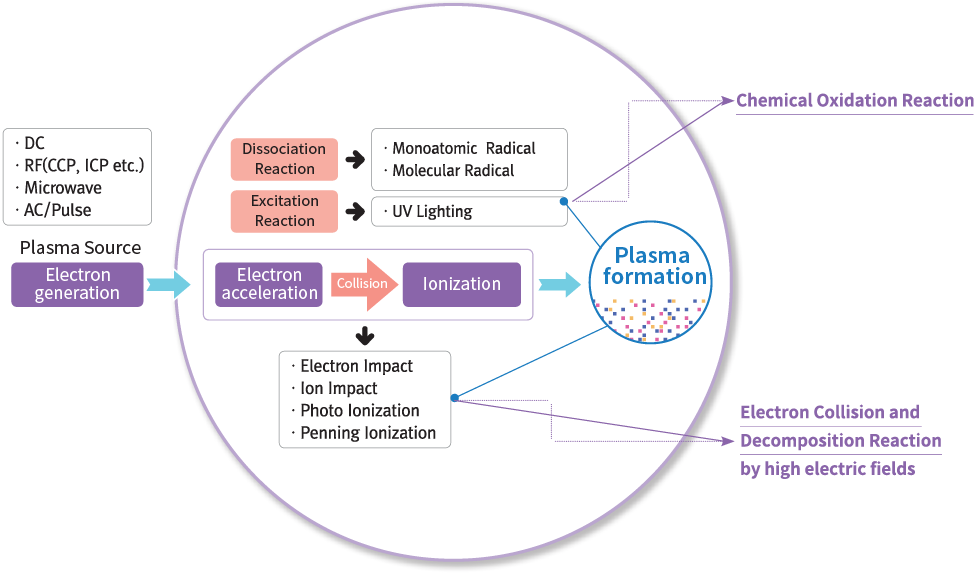

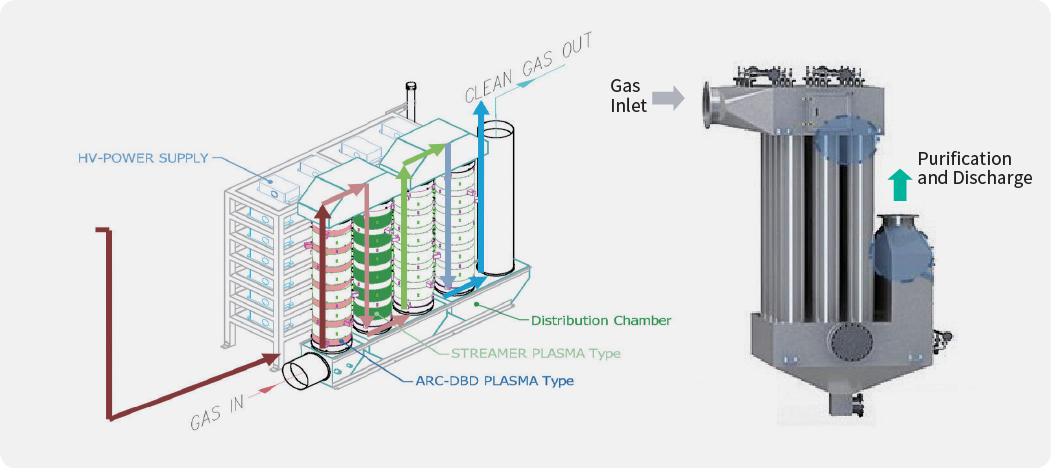

- Plasma unit processes or multi-stage process systems applied according to the concentration and volume of complex odors and hazardous gases (pry Humid) (Max. 1.5 [kW])

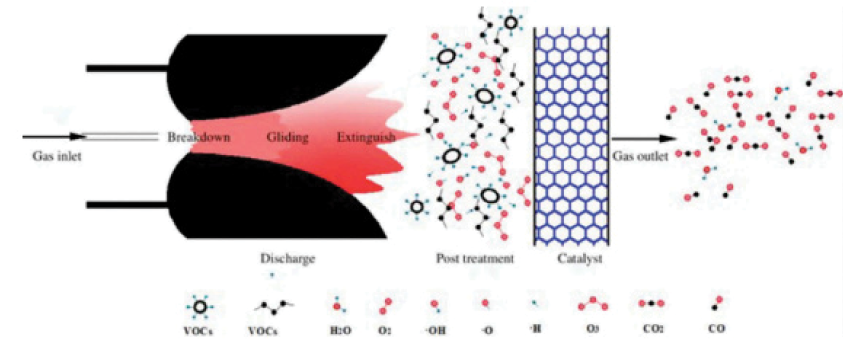

- Multi-stage connection of plasma channels → Reforming, decomposition, and oxidation of pollutants

- Implementation of heterogeneous discharge characteristics in a single process through an asymmetric electric field electrode structure (Non-Thermal & Quasi-Thermal) composite plasma system

Pollutants are treated through the interaction of several processes during plasma formation,

including inelastic collisions of accelerated electrons caused by high electric fields, the electro

physical energy of the plasma channel, and the chemical oxidation reactions of ionized and

generated active radicals.

- 2NH₃ + e⁻ + 60H⁻ → N₂ + 6H₂O

- 2NH₃ + e⁻ + 6HOO⁻ → N₂ + 6H₂O + 3O₂

- H₂S + e⁻ + OH⁻ → S(↓) + H₂O + H⁺

- H₂S + e⁻ + HOO⁻ → S(↓) + H₂O + OH⁻

- HCHO + e⁻ + 2OH⁻ → CO₂ + H₂O + H₂

- HCHO + e⁻ + HOO⁻ → CO₂ + H₂O + H⁺

- CH₃CHO + e⁻ + 5OH⁻ + O₂ → 2CO₂ + 4H₂O + H⁺

- CH₃CHO + e⁻ + 2HOO⁻ + O₂ → 2CO₂ + 3H₂O

- C₇H₈ + e⁻ + 18OH⁻ + 5O₂ → 7CO₂ + 13H₂O + O

- C₇H₈ + e⁻ + 9HOO⁻ + 2O₂ → 7CO₂ + 8H₂O + H⁺